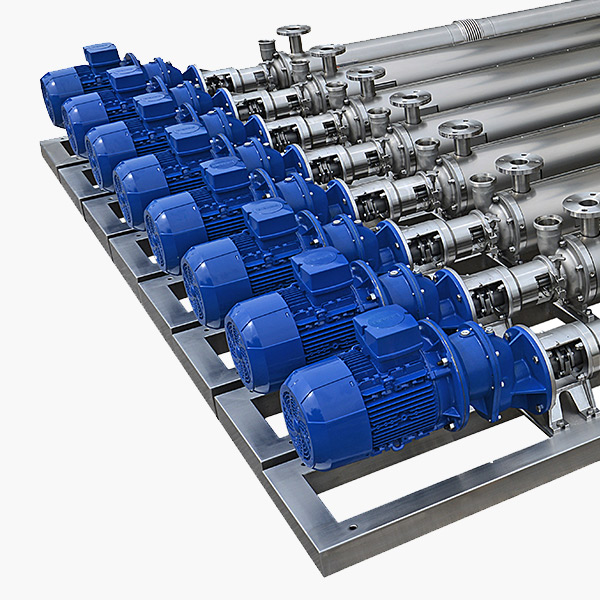

Hercules

The Hercules' project started several years ago in co-operation with the University of Parma. Several tests, ran on different products, have brought to the correct heat exchange coefficients and the power absorption, which allow MBS to develop a tailor-made calculation program to obtain the maximum efficiency from the heat exchangers.

Detailed description

How it works

l) The product enters and leaves the heat exchanger through specially profiled cylinder heads, which are designed for easy product flow and low stress; especially good for the safe processing of shear sensitive fluids.

2) Blades attached to the rotating shaft, create a gentle and high~ effective recirculation action as the product passes through the heat exchange cylinder; this ensures that an even temperature is achieved throughout the fluid.

3) IThe service media, which normally flows “counter current” through the cylinder shell, can provide efficient heating or cooling over a wide range of medium to high viscosity products.

Advantages

– Reliable Heat Transfer with Challenging Products

– High Thermal Efficiency with Gentle Handling

– Easy Disassembly and Inspection.

– Low Maintenance requirements.

Application range

Ideal for viscous and delicate products, particularly for those containing soft solids. Perfect for complex fluids which tend to ‘bum-on’, coat or solidify on hot or cold surfaces.

Products

Fruit pie filling, jams & preserves, ketchup. mayonnaise, chocolate, sauces, soups, ready meals, ragù, gelatin, baby food. honey. sugar. confectionery. butter. cheese curd, ice cream, oils, fats, emulsions, liquid egg etc.