From the design to the finished product

MBS is aware that in order to produce a high quality product, all single components involved in the production process has to be planned and built with high quality standards.

For this reason we believe it is important to understand the customer’s needs taking care of every single request according to the type of product. Our customers are really satisfied and they report us that an optimize design of the heat exchanger positively affect quality and energy saving.

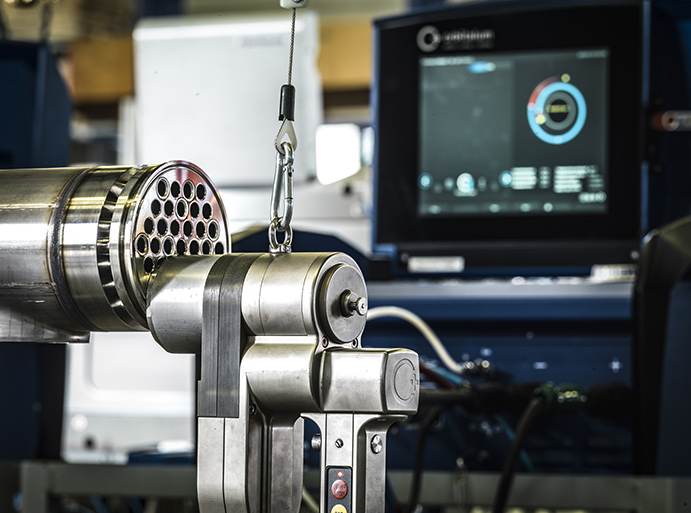

Production phase

First of all let’s proceed with the sizing phase: depending on the products and the duty the heat exchanger is sized thanks to an internal calculation program which consider our own profiles and corrugation depth performed on the tubes.

Then there is the design phase: the technical department thanks to advanced software and technologies, proceeds to the realization of the production drawing considering the main normative and regulations for pressure vessel.

Finally the project goes to the production department where a highly qualified staff proceeds with an extreme attention to details in all different stages:

• Corrugation • Satin finish • Skirting • Welding • Trimming • Expanding • Polishing

Final Phase

Last but not least we proceed with the testing phase where different tests are carried out to ensure a high quality product.

The final result it is not a simple heat exchanger but a product that saves energy, that makes the raw material as good as possible and that does not alter it.