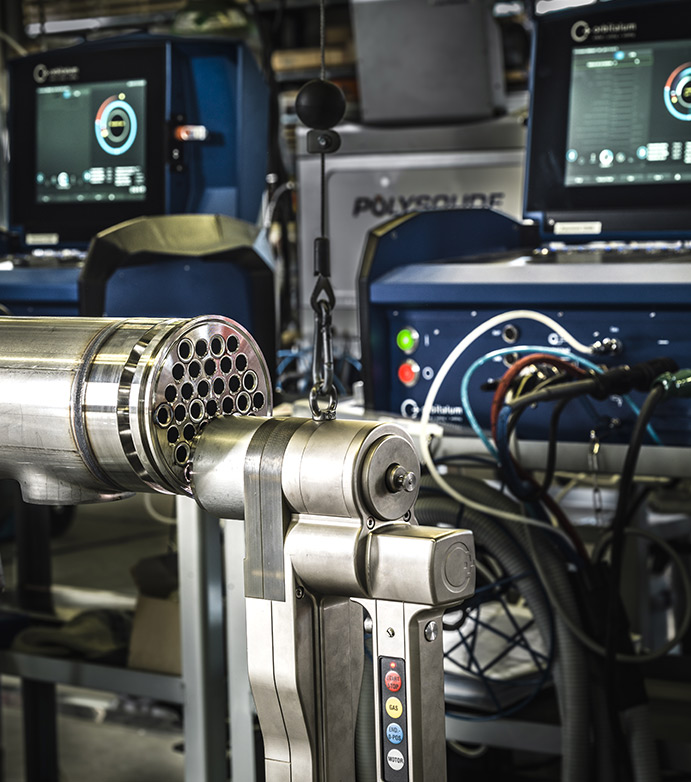

Corrugated tubular heat exchangers

Corrugation is a particular processing applied on plain tubes to induce dynamic turbulence during the liquids flowing allowing thermal exchange optimization.

With corrugated tubes the thermal exchange efficiency con be enhanced by 40% up to 90% according to the following parameters:

• type of product

• selected profile

• type of application

Advantages

• reduced exchange surfaces

• reduced contact and standing product time inside the element

• reduced washing time thanks to a higher action produced by turbulence

• vertical or horizontal installation

• working possibilities with high pressures and temperatures

• gaskets-free design so lower maintenance costs

• easy to install and exchanger modularity

Planning

With a program planning we own and which considers our profiles and corrugation depth we reach the exchanger right dimension, based on products and type of work. After dimensioning the exchanger, the technical office realizes the construction drawing considering the most important law regulations. Greatest details care and aimed realizations depending on different product fields.

• Corrugation

• Satin finishing

• Skirting

• Welding

• Trimming

• Expanding

• Polishing

• Testing